About the Project

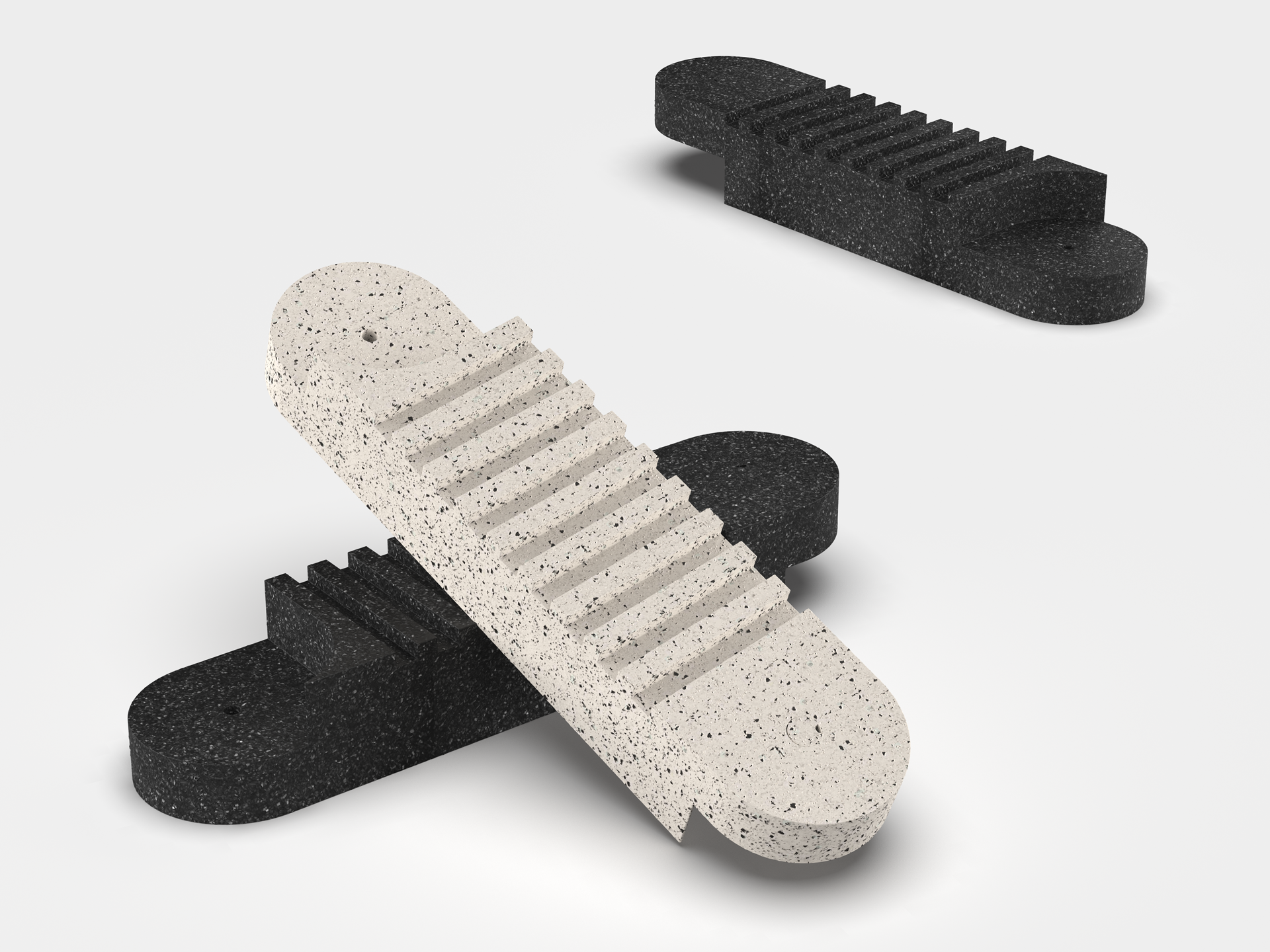

The project uses 100% waste: granulate from ground car tires and recycling from grinding waste from transition materials (mainly HDPE). There are no admixtures of the new material, additional binder or pigments.

The mixture, prepared in the right proportion of plastic to rubber, is pressed in a mold, which makes technical service a service very simple. Pre-inspection samples tested by the lab professionals that have been removed from the materials.

Behavioral Assessment Design Process. The finished product is to be recycled in appropriate cycles.

The bumper can be installed as a parking stop at the facades of the building or as an element separating the road lanes from the parking lot, etc. Thanks to the elasticity of the material, it perfectly absorbs impacts and protects objects against damage.

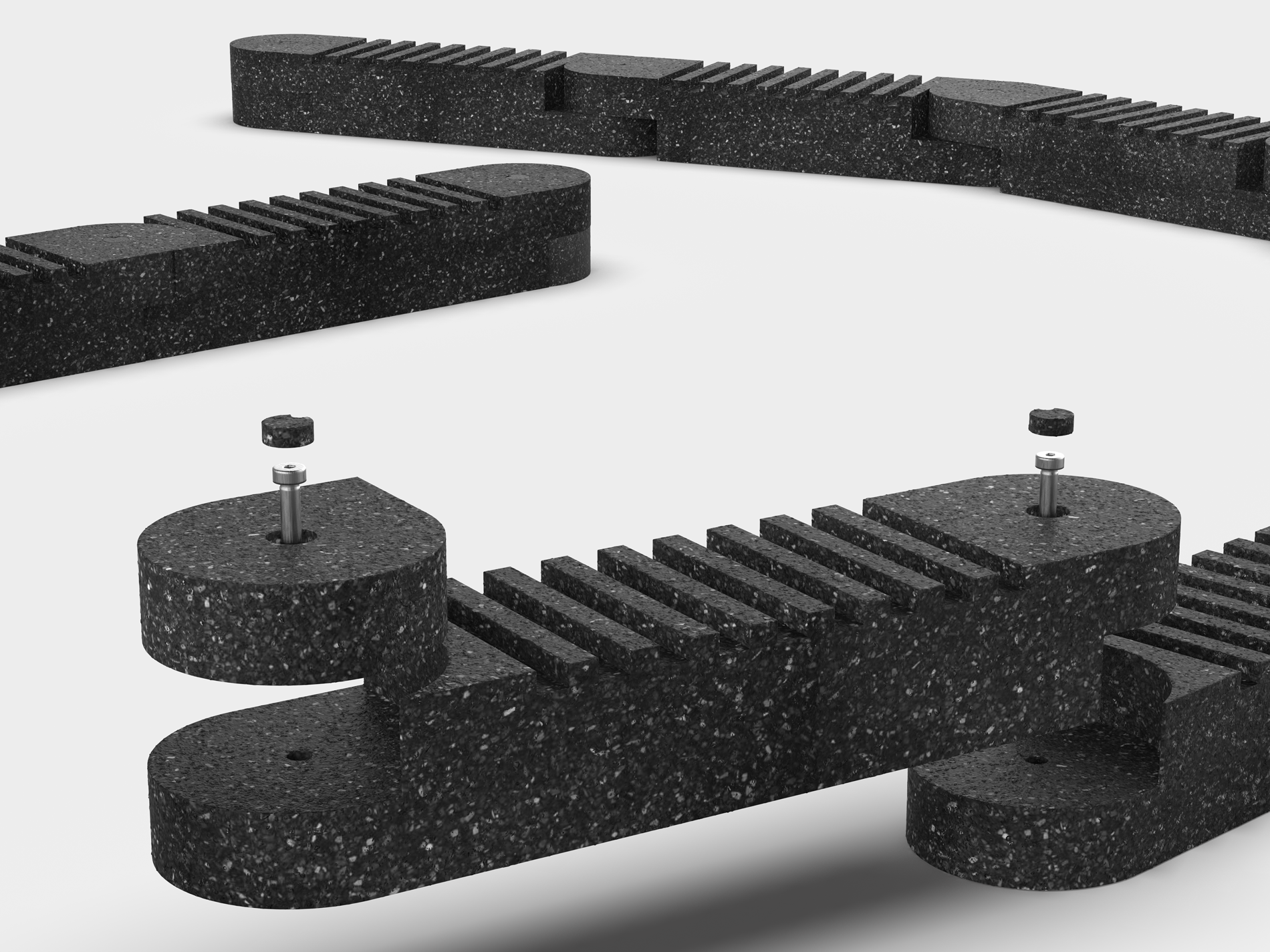

Each module can be rotated relative to the other, so we can build curbs with almost any straight or curved line. Plugs are used on the end of the modules.

Modules are mounted to the ground using the standard expansion plugs.